Pearl quality control checklist matters when you’re sourcing thousands of strands. One bad batch can wreck your reputation. Miss a critical defect? Your customer notices before you do.

You can’t scale a pearl business on gut feeling alone. A proper pearl quality control checklist eliminates guesswork and keeps your team aligned on what “acceptable” actually means.

Think of it this way: Would you trust someone to pick 10,000 pearls based on “they look nice”? Exactly. Standards matter when your brand is on the line.

Most wholesale pearls suppliers fail because they skip this step. They assume their team knows quality when they see it. Then a shipment arrives with half the strand showing visible wrinkles or poor luster. Customer calls. Refund issued. Reputation damaged.

The truth? Even experienced graders need a written pearl quality control checklist to stay consistent across inspections.

At Xinye Pearl, we specialize in freshwater pearls – the workhorses of the pearl industry. Modern freshwater pearl cultivation includes both traditional solid-nacre pearls and newer bead-nucleated varieties. Your pearl quality control checklist needs to accommodate both types effectively.

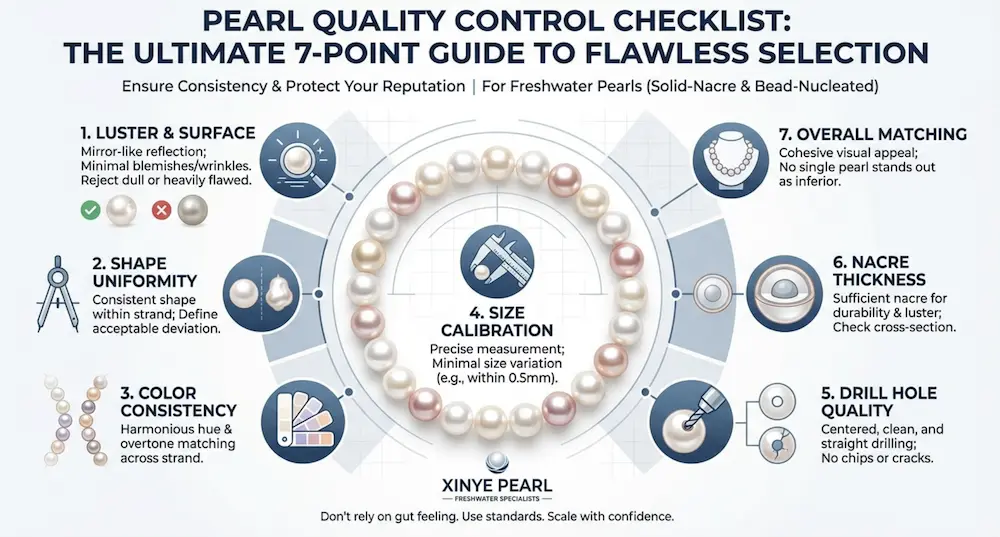

The 7 Critical Factors In Any Pearl Quality Control Checklist

Here’s where most guides get fluffy. They tell you pearls need “good luster” without defining what that actually looks like under inspection lights. Let me break down the real checkpoints we use for freshwater pearl grading.

1. Luster Assessment

This is non-negotiable. A pearl without sharp luster is just a dull bead. Your pearl quality control checklist should include:

- Mirror test: Can you see facial features reflected on the pearl surface?

- Light edge definition: Are reflected light sources crisp or blurry?

- Depth of glow: Does light appear to come from within multiple nacre layers?

Hold the pearl one foot away under daylight-equivalent lighting. If reflections blur or appear chalky, it fails the luster checkpoint. According to GIA’s evaluation standards, luster ranks as the most critical value factor because it directly indicates nacre quality.

Freshwater pearl luster grades for your pearl quality control checklist:

- AAAAA: Mirror-like reflections, extremely sharp edges, deep inner glow

- AAAA: Excellent reflections with crisp edges

- AAA: Very good reflections, slight softness at edges

- AA: Good reflections but somewhat hazy

- A: Visible reflections but minimal depth, somewhat dull

2. Surface Quality Inspection

Your pearl quality control checklist needs specific defect categories. Don’t just write “check for blemishes.” Define them.

Common surface characteristics to document:

- Abrasions (scratches affecting luster)

- Bumps (raised irregularities)

- Pits (small depressions)

- Wrinkles (uneven nacre texture – common in freshwater)

- Chips or gaps (durability concerns)

- Spots (color variations)

Here’s how surface quality maps to freshwater pearl grades in your pearl quality control checklist:

| Grade | Surface Quality Standard | What It Means |

|---|---|---|

| AAAAA | 100% clean surface | Zero visible imperfections to naked eye |

| AAAA | 95%+ clean | One or two tiny spots not visible at arm’s length |

| AAA | 90%+ clean | Minor surface characteristics not affecting overall appearance |

| AA | 75%+ clean | Some visible imperfections but still attractive |

| A | 50%+ clean | Multiple visible surface characteristics |

Here’s the catch most people miss – a tiny flaw near the drill hole? Acceptable for higher grades. A visible pit on the front of an earring pearl? Hard fail. Location matters as much as severity on your pearl quality control checklist.

3. Shape Evaluation

Freshwater pearls naturally tend to be potato-shaped, oval, almost round or round. Your pearl quality control checklist should accommodate this reality rather than penalize pearls for being authentically freshwater.

Shape standards for freshwater pearls:

- AAAAA: Perfectly round (less than 1% variation from spherical)

- AAAA: Near-round (1-3% variation)

- AAA: Off-round (3-5% variation)

- AA: Semi-baroque (5-8% variation)

- A: Baroque (over 8% variation)

When inspecting freshwater pearls, roll them on a flat surface. Truly round pearls will roll smoothly. Off-round pearls will wobble. Your pearl quality control checklist should note this test result.

At Xinye Pearl, we see customers increasingly appreciate baroque pearls for contemporary jewelry. Don’t automatically downgrade a pearl just because it’s not round – evaluate shape against the intended use case.

4. Nacre Thickness Verification

Here’s where your pearl quality control checklist must differentiate between two types of freshwater pearls:

Traditional Tissue-Nucleated Freshwater Pearls (Solid Nacre): These are all nacre, no bead inside. They’re more durable because scratches just reveal more nacre underneath.

Bead-Nucleated Freshwater Pearls: New ways of growing pearls now make freshwater pearls with bead nuclei, which are like Akoya pearls. These make rounder shapes and are faster to make, but you need to check the thickness of the nacre.

What your pearl quality control checklist SHOULD check:

For bead-nucleated freshwater pearls:

- Examine drill holes for nacre layer thickness

- Minimum acceptable nacre: 0.4-0.5mm on each side

- Look for the transition line between nacre and bead nucleus

- Verify consistent nacre coverage across the entire pearl

For solid-nacre freshwater pearls:

- Examine drill holes for consistent nacre structure

- Look for any signs of hollow centers (rare but possible)

- Verify nacre hasn’t been artificially enhanced or coated

Important checkpoint: If you can see the bead nucleus through thin patches or at the drill hole, the pearl does not meet quality criteria. Put “reject” or “severe downgrade” next to it on your pearl quality control checklist.

At Xinye Pearl, we work with both types. The key is knowing which you’re inspecting and applying the right standards from your pearl quality control checklist. Bead-nucleated freshwater pearls with thin nacre won’t last – that’s non-negotiable.

5. Color Consistency And Matching

From white to cream to peach to pink to lavender and more, freshwater pearls come in a huge range of natural colors. The way you check the color of your pearls must be different from how you check the color of Akoya or South Sea pearls.

For individual freshwater pearls, document:

- Bodycolor (dominant overall color)

- Overtone (translucent color layer)

- Uniformity (consistent color across the pearl)

For strands and pairs, verify:

- Progressive color graduation across the strand

- No abrupt color shifts between adjacent pearls

- Consistent overtone throughout

- Near-identical matching in earring pairs

Pro tip from our pearl quality control checklist: Always grade color against a neutral white background. Black backgrounds make pearls look better than they actually are – a trick some suppliers use to hide mediocre quality.

Color doesn’t affect grade tier (AAAAA through A) in our system – a perfectly clean, lustrous lavender pearl is still AAAAA grade. Color is a preference factor, not a quality factor.

6. Size Uniformity

Your pearl quality control checklist should include precise size measurements in millimeters. A “9mm strand” that actually ranges from 8.2 to 9.8mm isn’t acceptable for premium buyers.

Freshwater pearl size uniformity standards:

- AAAAA/AAAA: Maximum 0.5mm variation within strands

- AAA: Up to 0.7mm variation acceptable

- AA: Up to 1mm variation

- A: Over 1mm variation (budget tier)

Use digital calipers. Eye-balling doesn’t cut it when you’re processing hundreds of strands weekly. Your pearl quality control checklist should have actual measurement fields, not just “looks consistent.”

Freshwater pearls typically range from 4mm to 12mm, with 7-9mm being the sweet spot for commercial strands. Note this on your pearl quality control checklist for inventory planning.

7. Drill Hole Quality

Drill holes, which are easy to miss, tell you everything you need to know about production standards. The following should be on your pearl quality control list:

- Off-center drilling (affects drape and appearance)

- Rough or chipped edges around the hole

- Inconsistent hole diameter (stringing nightmare)

- Proper hole size (typically 0.6-1mm for freshwater strands)

A properly executed pearl quality control checklist catches these issues before pearls reach the stringing stage. At Xinye Pearl, we reject entire batches if more than 2% show poor drilling – it signals careless production standards.

How To Implement Your Pearl Quality Control Checklist For Freshwater Pearls

Theory means nothing without execution. Here’s how we actually use these checklists at scale:

Step 1: Train Your Team On The Pearl Quality Control Checklist

Don’t assume people understand “excellent luster.” Show them. Use master pearls representing each grade level. Have new graders compare their assessments against experienced staff.

Training protocol we follow:

- New graders spend 2 weeks comparing their assessments against masters

- They must achieve 95% accuracy before working independently

- Monthly re-calibration sessions with the full team

- Blind tests using the pearl quality control checklist to catch drift

Step 2: Document Everything

Your pearl quality control checklist should be a living document with checkboxes and space for notes. When you reject a batch, you need specific documentation showing which criteria failed.

We use a simple spreadsheet format:

- Supplier name and batch ID

- Date inspected and inspector name

- Grade assigned (AAAAA through A)

- Specific defects noted

- Accept/reject/rework decision

This creates a quality history. Three rejected batches from one supplier? Time for a serious conversation about their production standards.

Step 3: Random Audit Inspections

Even with a solid pearl quality control checklist, inspector fatigue happens. We randomly re-inspect 10% of already-graded inventory to ensure standards hold.

When audit results differ from original grading by more than one grade level, we investigate. Either the inspector needs retraining or the pearl quality control checklist needs clearer criteria.

FAQs About Pearl Quality Control Checklist Implementation

How often should I update my pearl quality control checklist?

Review quarterly. Update immediately if you see pattern issues from suppliers or customer complaints about specific defects your checklist missed. We revised ours six times the first year before it stabilized.

Why do freshwater pearls use a five-tier grading system instead of three?

Freshwater pearls show wider natural variation than bead-nucleated pearls. The AAAAA-A system captures these nuances better. A three-tier system (AAA, AA, A) doesn’t give enough differentiation for buyers who want to understand exactly what they’re getting.

How many pearls should I inspect per batch?

For routine suppliers with proven quality, inspect 10% of each batch using your pearl quality control checklist. For new suppliers or those with previous issues, inspect 100% until they demonstrate consistent quality.

What’s the difference between tissue-nucleated and bead-nucleated freshwater pearls?

Tissue-nucleated freshwater pearls are solid nacre throughout – no bead inside. They take 3-6 years to cultivate and trend toward baroque or near-round shapes. Bead-nucleated freshwater pearls have a shell bead nucleus (like Akoya) and produce rounder shapes in 1-2 years. Your pearl quality control checklist needs nacre thickness verification for bead-nucleated but not for tissue-nucleated varieties.

Can I upgrade pearls through better drilling or stringing?

No. Your pearl quality control checklist should grade pearls based on their inherent characteristics – luster, surface, shape, size. Processing quality matters for final product value, but a AA-grade pearl with perfect drilling is still a AA-grade pearl.

What’s the price difference between grade levels?

Roughly speaking, each grade level down represents about a 30-40% price reduction. AAAAA freshwater pearls might wholesale at $300 per strand, while AAA drops to $120, and A-grade sells for $40. Your pearl quality control checklist directly impacts revenue.

Should my pearl quality control checklist account for color preferences?

Color is preference, not quality. A perfectly lustrous, clean lavender pearl ranks AAAAA just like a white one. However, you should note color on inspection forms for inventory management – some colors command premium prices based on market trends.

Final Thoughts On Your Pearl Quality Control Checklist

A pearl quality control checklist isn’t bureaucracy. It’s the difference between building a sustainable business and constantly firefighting quality disasters.

At Xinye Pearl, our reputation rides on freshwater pearls that meet the grades we promise. Whether we’re handling traditional solid-nacre pearls or modern bead-nucleated varieties, customers know exactly what they’re getting when we stamp a grade – AAAA means 95%+ clean surface, excellent luster, near-round shape, and consistent sizing.

Your pearl quality control checklist is your promise to customers. It defines what your brand stands for when you stamp a grade on a strand. Every pearl that leaves your facility represents your brand. Make your pearl quality control checklist the guardrail that protects it.