Have you ever wondered how those beautiful pearl necklaces obtain their perfect holes? The thing is, drilling pearls isn’t magic. The difference between amateur work and professional work—and therefore the quality of the finished jewelry—lies in the skill level and the mastery of how pearls are drilled.

We have drilled millions of pearls at Xinye Pearl over the years. And let me be clear: if you make one mistake, you’ll have broken nacre and wasted stock. But when you get the technique right? You’re making jewellery that will last for a long time.

What Makes Pearl Drilling Different from Other Gemstones

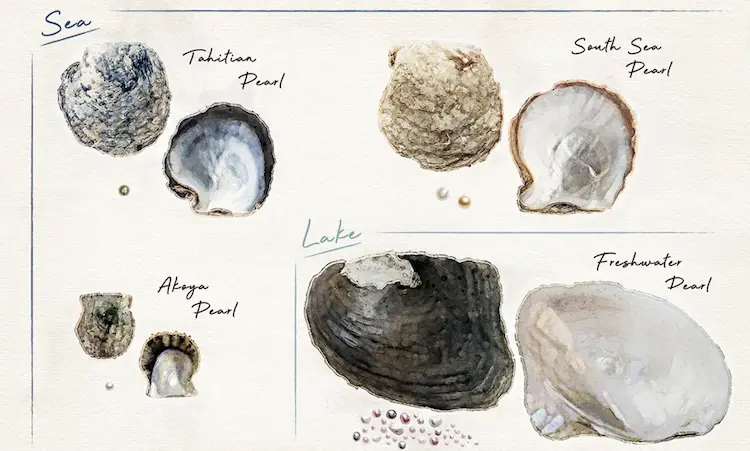

Pearls aren’t your typical stones. Their nacre layers are delicate, and the nucleus inside can be unpredictable. That’s why understanding how pearls are drilled properly matters for anyone serious about the jewelry business.

The softness factor is real. While diamonds score a 10 on the Mohs scale, pearls sit at a modest 2.5-4.5. This means they require completely different drilling approaches. Push too hard? The pearl cracks. Go too slow? Your drill bit binds up and damages the surface.

Here’s what you’re dealing with:

- Nacre thickness varies – Some freshwater pearls have solid nacre throughout, while others have thinner layers over a bead nucleus

- Surface irregularities – Baroque pearls need custom positioning that round pearls don’t

- Temperature sensitivity – Friction generates heat that can damage the organic calcium carbonate structure

The 2 Primary Methods of How Pearls Are Drilled

Full-Drilling Technique

Full-drilling creates a hole completely through the pearl. This method is standard for necklaces, bracelets, and any strung jewelry pieces. The key to professional results in how pearls are drilled? Never drill straight through from one side.

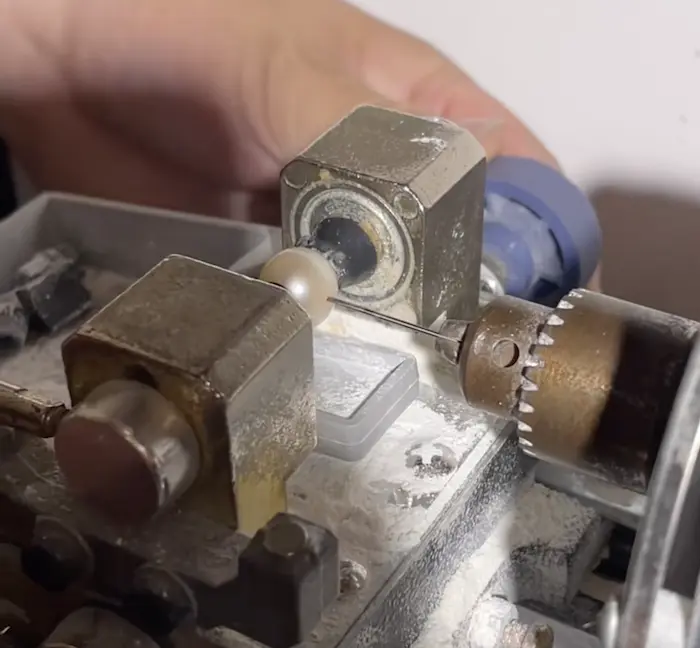

Professional Pearl Manufacturers use a two-sided approach. Drill halfway from one side, flip the pearl 180 degrees, then drill from the opposite side to meet in the middle. Why? It prevents the exit-side blowout that ruins the pearl’s surface as the drill bit breaks through.

According to Gemological Institute of America, this technique preserves the pearl’s structural integrity and creates cleaner holes with minimal surface damage.

Half-Drilling Method

Half-drilling goes partway into the pearl—typically used for earrings, rings, and pendants mounted on posts. The process is simpler than full-drilling but demands equal precision in mastering how pearls are drilled.

You’re creating a seat for glue and a mounting post. Drill too shallow and the post won’t hold. Drill too deep and you risk compromising the pearl’s strength. The sweet spot? Usually 3-5mm depth depending on pearl size.

Essential Equipment for Professional Pearl Drilling

Let’s talk tools. Your results are only as good as your equipment. Period.

Standard Pearl Drilling Machine Components:

| Component | Purpose | Why It Matters |

|---|---|---|

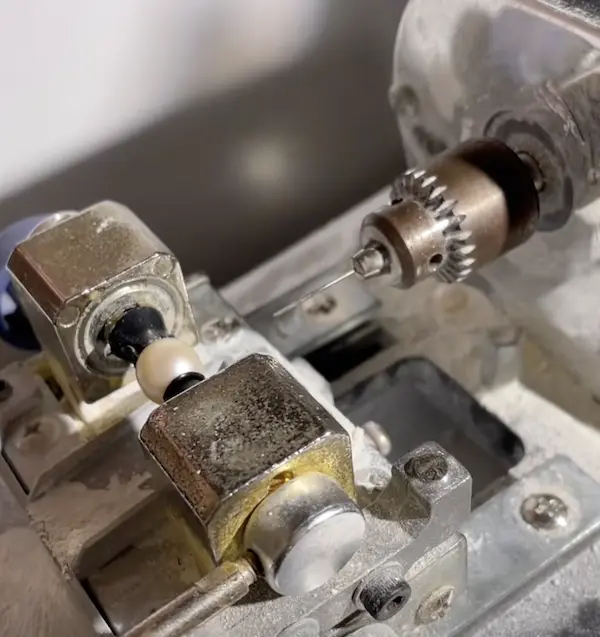

| Pearl vice with brass cups | Holds pearl securely | Prevents slipping and surface scratches |

| Variable speed motor | Controls drill RPM | Allows speed adjustment for different pearl types |

| Depth gauge | Measures drill depth | Ensures consistent hole depth |

| Diamond drill bits (0.6-3.5mm) | Creates the hole | Diamond coating cuts cleanly with minimal heat generation |

| Dust collection system | Removes pearl dust | Keeps work area clean and safe |

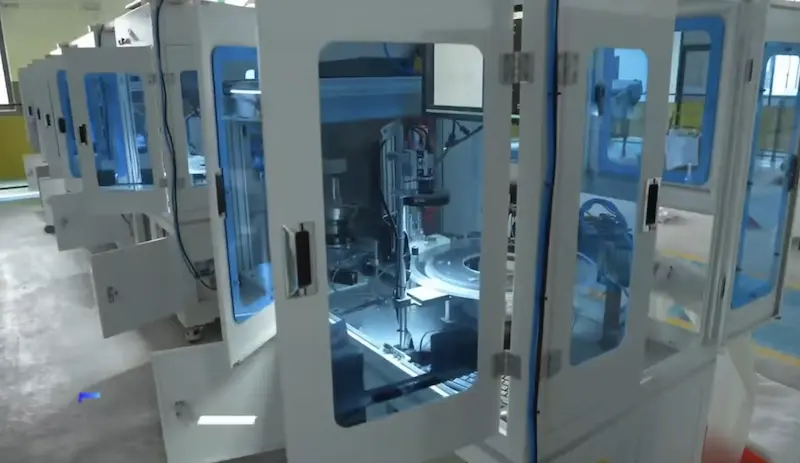

Wholesale pearls suppliers like us use industrial-grade machines that can drill 1,000+ pearls per session. Here’s the reality for freshwater pearl operations – we don’t use water cooling. The drilling happens quickly enough that heat buildup isn’t an issue when you’re using proper technique and sharp diamond bits.

Small-scale jewelers can achieve professional results with a quality flexible shaft tool (like a Dremel), proper pearl vise, and diamond burs. The key is using the right speed and not applying excessive pressure that generates friction heat.

The drill bit selection matters more than most realize. Standard twist bits work but wear out fast. Diamond-coated bits last longer and create smoother holes. For freshwater pearls, a 0.6mm starter bit is industry standard, according to research published by Stuller Inc..

Step-by-Step: How Pearls Are Drilled in Commercial Operations

Step 1: Mark the Drill Point

Identify the pearl’s best face – the side with minimal blemishes and optimal luster. Mark it with a water-based pen. For full-drilling, use a micrometer to find the exact center axis. This isn’t optional if you want straight holes.

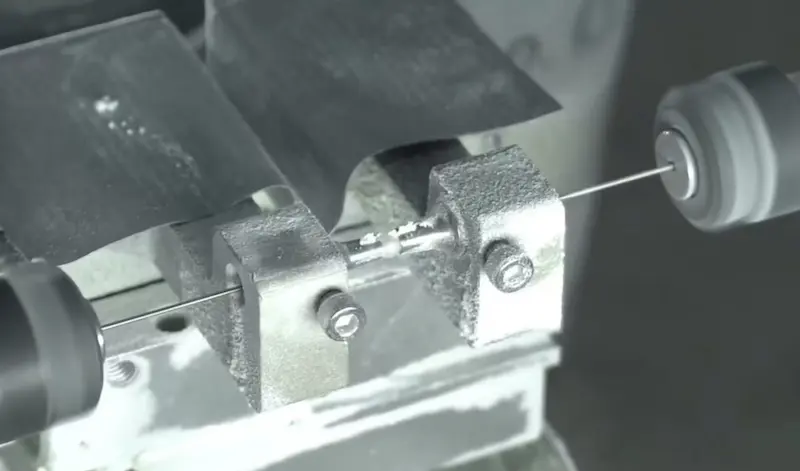

Step 2: Secure the Pearl

Place the pearl between brass or nylon cups in your pearl vise. The cups should match your pearl’s curvature. For baroque shapes, use padding or adjustable cups. Tighten firmly but not so hard you crack the pearl.

Step 3: Align Your Drill

Position the drill bit at your marked spot. Double-check alignment by bringing the pearl to the bit without turning it on. If it’s off-center, adjust now. Once drilling starts, there’s no fixing misalignment.

Step 4: Begin Drilling

Start your motor at medium-high speed (8,000-12,000 RPM for most pearls). Apply gentle, consistent pressure. Let the bit do the work. Every 2-3 seconds, retract slightly to clear debris.

For full-drilling, drill to your halfway depth mark, stop, rotate the pearl 180 degrees, and drill from the opposite side. This is how pearls are drilled to avoid surface chipping at the exit point. The quick drilling action with sharp diamond bits prevents heat buildup – that’s why freshwater pearl factories can process thousands of pearls daily without cooling systems.

Step 5: Clean and Inspect

Remove the pearl and tap out any remaining dust. Inspect the hole for:

- Clean entry and exit points (no chipping)

- Straight alignment (pass a wire through to check)

- Appropriate diameter for your intended use

Wipe the pearl clean with a soft cloth. Any surface marks from the vise should be minimal and located away from visible areas.

Common Mistakes That Destroy Pearls During Drilling

I’ve seen countless pearls ruined by these errors:

- Excessive pressure – Pearls need time. Rushing creates cracks in the nacre layers that spread over time. The pearl might look fine initially but will fail after stringing.

- No cooling water – Friction heat breaks down the protein that binds the calcium carbonate crystals. You’ll see yellowing or chalky appearance around the hole. Once heat-damaged, there’s no fixing it.

- Wrong drill speed – Too slow and the bit catches and tears. Too fast and you generate excessive heat. The goldilocks zone for understanding how pearls are drilled sits around 8,000-12,000 RPM.

- Single-side full drilling – We covered this, but it’s worth repeating. Drilling all the way through from one side creates massive chipping when the bit exits. It’s the number one amateur mistake.

- Skipping alignment checks – Off-center holes look unprofessional and weaken the pearl structure. Take 30 extra seconds to verify alignment before drilling.

Different Holes for Different Jewelry Styles

Not all pearl holes are created equal. Your drilling approach should match the final jewelry design:

- Standard necklace/bracelet holes: 0.6-1.0mm diameter, full-drilled through center

- Large-hole bead designs: 2.5-3.5mm diameter, requires progressive drilling with increasing bit sizes

- Post-mounted earrings/rings: 3-4mm depth, half-drilled, sized for snug post fit

- Top-drilled pendants: Drilled through the top with smaller diameter, often at an angle

The key to understanding how pearls are drilled for different applications is matching hole specifications to the mechanical requirements of the jewelry piece.

Quality Control: What Professional Manufacturers Check

At Xinye Pearl, every drilled pearl goes through inspection. Here’s what we look for:

- Hole straightness – We pass a needle through full-drilled pearls. Any binding indicates misalignment. Reject rate on this alone? About 2-3% even with experienced operators.

- Surface integrity – Entry and exit points should be clean with minimal chipping. A little roughness is acceptable if it’s covered by findings, but visible damage means rejection.

- Diameter consistency – When drilling batches, hole sizes must match. Inconsistency creates problems during stringing and knotting.

- Depth accuracy for half-drills – Use a depth gauge to verify each pearl. Variations of more than 0.5mm cause mounting issues.

How Modern Technology Changed Pearl Drilling

Traditional pearl drilling used bow drills operated by hand. Craftsmen would drill a few hundred pearls per day maximum. Now? Automated systems can process thousands per hour with better precision.

CNC-controlled pearl drilling machines can handle complex patterns and off-center holes that would be nearly impossible manually. But understanding how pearls are drilled fundamentally hasn’t changed – it’s still about controlled pressure, proper cooling, and two-sided approach for through-holes.

The biggest advancement isn’t speed – it’s consistency. Modern equipment produces uniform results that manual drilling could never match at scale.

Frequently Asked Questions

Why can’t I just drill a pearl with a regular drill bit?

You can, technically. But regular twist bits dull quickly on calcium carbonate and generate more heat than diamond-coated bits. They work for one or two pearls if you’re careful with speed and pressure, but they’re not viable for quality work or production quantities. Sharp diamond bits cut efficiently without heat buildup.

How long does it take to drill a single pearl?

For experienced operators with proper equipment, 30-45 seconds per pearl for standard full-drilling. Half-drilling takes 15-20 seconds. Large-hole drilling with progressive bit sizes can take 2-3 minutes per pearl.

Can you re-drill a pearl to make the hole larger?

Yes, but it’s riskier than drilling fresh. Use progressively larger diamond burs, increasing size gradually. Go straight from 0.6mm to 3mm and you’ll likely crack it. Step up in 0.5mm increments.

What causes pearl holes to look yellow or discolored?

Heat damage from excessive friction during drilling. This happens when using dull bits, applying too much pressure, or drilling at incorrect speeds. The protein matrix in the nacre breaks down from heat, causing permanent discoloration. Using sharp diamond bits and proper technique prevents this issue – that’s why professional factories can drill rapidly without cooling systems.

Do all pearls need to be drilled from both sides?

For through-holes, yes. Half-drills obviously only need one side. But for full-drilling, the two-sided approach prevents exit-side blowout. Some operators claim they can drill through in one pass, but the failure rate isn’t worth it for professional work.

Final Thoughts: Mastering Pearl Drilling Takes Practice

Understanding how pearls are drilled intellectually is one thing. Developing the feel for proper pressure and technique takes repetition. We’ve trained dozens of operators at Xinye Pearl, and the learning curve typically runs 2-3 weeks before someone can produce consistently clean holes.

Start with lower-value pearls to practice. Get your technique dialed in before working with premium pieces. And remember – slow and steady beats fast and sloppy every single time in this business.

The pearl jewelry industry depends on quality drilling. Master this fundamental skill, and you’ll separate yourself from competitors who cut corners. Because at the end of the day, how pearls are drilled determines whether a piece lasts a season or a lifetime.