Full-drill vs half-drill pearls—this isn’t just industry jargon. It’s the decision that determines whether your jewelry piece looks professional or amateur. As a pearl manufacturer, we’ve seen too many jewelry makers order the wrong drilling specification and end up with inventory they can’t use.

Here’s what you need to know about drilling specifications before you place your next pearl order.

What Full-Drill and Half-Drill Actually Mean

Let’s cut through the confusion.

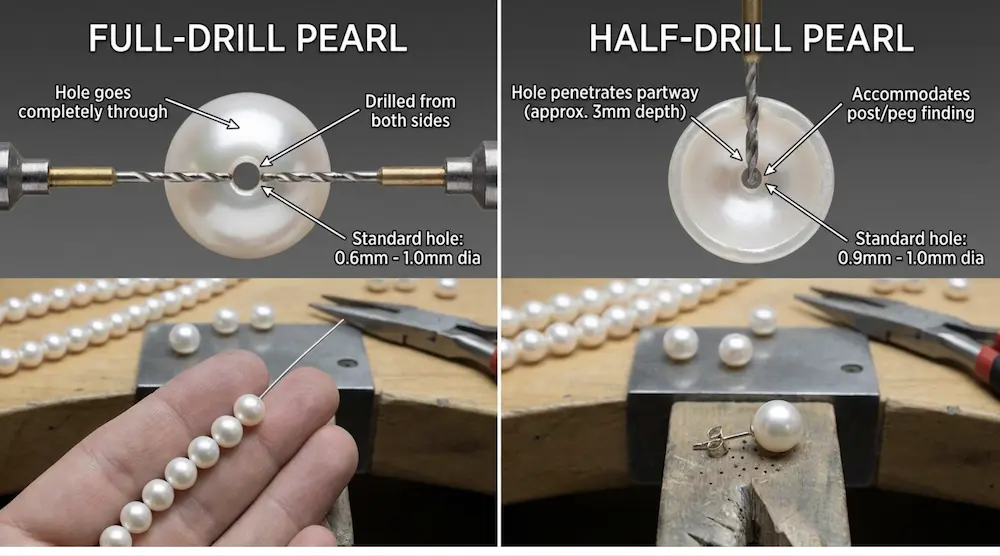

Full-drill pearls have a hole that goes completely through the pearl from one side to the other. The pearl is drilled from both sides to meet in the middle—never straight through in one pass, which would risk cracking the nacre. The standard hole size runs about 0.6mm to 1.0mm in diameter.

Half-drill pearls have a hole that only penetrates partway into the pearl, typically just deep enough to accommodate a post or peg finding. Despite the name, these aren’t drilled exactly halfway through. For a 6-8mm pearl, you’re looking at roughly 3mm of depth, give or take. The standard hole size runs about 0.9mm to 1.0mm above in diameter.

The drilling method you choose isn’t about aesthetics. It’s about function.

When to Spec Full-Drill Pearls in Your Designs

Full-drill vs half-drill pearls comes down to one question: how does the pearl attach to your jewelry?

Full-drill pearls work when you need the pearl to:

- Thread onto wire, cord, or chain for necklaces and bracelets

- Pass through with a pin for certain antique-style settings (think crown jewels)

- Suspend from jump rings for tin cup necklaces or floating designs

- Link together with wire wrapping techniques

When you’re sourcing wholesale pearls for strung jewelry, full-drill is your only option. The hole needs to go all the way through. No workarounds here.

But here’s the catch: full-drill earrings can look “beader-y”—like leftover pearls from a broken necklace. Unless you’re deliberately going for that vintage pin-through aesthetic, half-drill usually delivers a cleaner look for studs and drops.

Half-Drill Pearls: The Professional Standard for Posts

For post-mounted jewelry, half-drill vs full-drill pearls isn’t even a debate.

Half-drill pearls deliver:

- Cleaner aesthetic with no visible hole on the front face

- Professional finish that conceals the mechanical attachment

- Better pearl presentation since the full bottom surface remains visible

- Optimal security when properly glued to findings

The key word there is “properly.” Half-drill pearls rely entirely on adhesive bond strength. We’re talking two-part epoxy—specifically Devcon 5-minute or equivalent. Not craft glue. Not super glue. Two-part epoxy rated for jewelry applications.

Mixed correctly and cured for 24 hours in a humidity-free environment, the bond is permanent. Mixed wrong or rushed? Your customer’s earring falls apart in three months.

Table: Full-Drill vs Half-Drill Application Guide

| Jewelry Type | Recommended Drill | Why |

|---|---|---|

| Stud Earrings | Half-Drill | Cleaner look, concealed attachment |

| Drop Earrings | Half-Drill (preferred) | Professional finish, though full-drill acceptable |

| Necklace Strands | Full-Drill | Must thread through |

| Tin Cup Necklaces | Full-Drill | Wire passes through pearl |

| Pearl Rings | Half-Drill | Posts mount into bezel cup |

| Bracelets | Full-Drill | Threading required |

| Pendants | Half-Drill | Better when mounted on bail or post |

The Manufacturing Reality: Drilling Costs Matter

Here’s what most jewelry designers don’t consider: full-drill vs half-drill pearls affects your cost structure.

Full-drilling requires:

- Two-sided drilling with precise alignment

- Higher breakage risk during production

- Specialized vises and alignment tools

- More QC to verify hole alignment

Half-drilling requires:

- Single-side drilling only

- Lower breakage risk

- Simpler tooling setup

- Faster production time

That translates to pricing. When you’re ordering custom drilling specifications on freshwater pearls, expect half-drill to run about 15-20% less than full-drill work—assuming you’re working with a manufacturer who knows what they’re doing.

At scale, those savings compound. Order 1,000 pearls? That pricing difference matters.

Technical Drilling Specifications You Need to Know

When you order from a wholesale pearls supplier, if you don’t give them clear instructions, you’ll get bad outcomes.

Be specific about:

- Hole diameter: Standard hole size is 0.6mm, 0.8mm, however you can also have custom sizes of 1.0mm, 1.3mm, 2.0mm, or 2.5mm for bigger threading materials.

- Drill depth for half-drill: Give the exact depth in millimetres based on the length of your post.

- Drill orientation: normal through-hole, top-drilled, or side-drilled

- Quality requirements: Chipping around the sides of the hole is okay (little vs. none)

Professional Pearl Manufacturers like Xinye Pearl can accommodate custom drilling in any diameter you need. But you have to ask. Don’t assume “standard” means what you think it means.

Common Drilling Problems and How to Avoid Them

Problem: The post breaks off inside the half-drilled pearl.

Reason: The hole isn’t deep enough or the adhesive bond isn’t strong enough.

Solution: Make sure the hole depth is at least 1mm deeper than the depth of the post insertion.

Problem: The holes from the full drill don’t line up

Cause: drilling with only one pass or not setting up the alignment correctly

Solution: Make sure the provider uses two-sided drilling with the right instruments for aligning.

Problem: Chipping around drill holes that can be seen

Cause: Bits that are too dull or a drill that is going too fast

Solution: Get your diamond bits from manufacturers who use new ones and follow the right RPM requirements.

Quality Control: What to Inspect When Your Order Arrives

Full-drill vs half-drill pearls both need inspection—but you’re looking for different defects.

Full-drill inspection checklist:

- Run a wire through each pearl to verify hole alignment

- Check for cracking or chipping at entry and exit points

- Measure hole diameter with a caliper

- Verify holes are centered on the pearl’s axis

Half-drill inspection checklist:

- Insert a test post to verify depth consistency

- Look for cracks radiating from the hole

- Check that the hole is perpendicular to the pearl face

- Verify hole diameter matches your finding specifications

If more than 2-3% of your order fails inspection, you’ve got a supplier quality problem.

How to Source Properly Drilled Pearls

Here’s the reality: most online pearl retailers don’t drill their own inventory. They’re middlemen dropshipping from factories they’ve never visited.

When you’re evaluating potential suppliers for full-drill vs half-drill pearls, ask:

- Do you drill in-house or outsource? In-house means faster turnaround and better QC

- What drilling equipment do you use? You want ultrasonic or precision motor drills, not hand drills

- Can I specify custom hole sizes? Flexibility indicates actual manufacturing capability

- What’s your breakage rate? Should be under 1% for quality operations

- Do you provide drill specification documentation? Professional manufacturers document their processes

At Xinye Pearl, we maintain in-house drilling operations with both standard and custom specifications. You want a 2.5mm hole in a baroque pearl? Done. Need 500 half-drilled 7mm rounds with precisely 3.2mm depth? We’ll have it drilled and quality-checked within your lead time.

That’s not bragging—it’s the baseline capability any serious Pearl Manufacturer should offer.

Design Considerations: Making the Right Call

Full-drill vs half-drill pearls isn’t always obvious in complex designs.

Design scenario 1: Convertible earrings

You want earrings that can convert from studs to drops. Solution? Order half-drill pearls for the stud position, full-drill for the drop pearls. Gives you design flexibility.

Design scenario 2: Mixed media pieces

Combining pearls with gemstones and metal beads? Full-drill pearls integrate seamlessly into stringing designs. They’ll match the functionality of your other components.

Design scenario 3: High-end statement pieces

For premium collections where appearance is everything, half-drill delivers that “this pearl was set specifically for this piece” look that full-drill can’t match.

The jewelry industry has standards for good reason. Half-drill for posts. Full-drill for threading. Deviate from that and you better have a compelling design reason.

The Bottom Line for Jewelry Makers

Full-drill vs half-drill pearls isn’t complicated once you understand the functional requirements.

- Use full-drill when the pearl needs to thread, slide, or pass through

- Use half-drill when the pearl mounts on a post, peg, or bail

- Specify exactly what you need when ordering from suppliers

- Inspect carefully when your order arrives

- Work with manufacturers who drill in-house and can accommodate custom specs

The right drilling specification makes your jewelry look professional. The wrong one makes it look like amateur hour.

At Xinye Pearl, we’ve been drilling pearls for jewelry manufacturers since before most of your competitors knew pearls came in colors other than white. We know the difference between a specification and a suggestion. When you order full-drill vs half-drill pearls from us, you get exactly what you ordered—checked, documented, and delivered on schedule.

That’s not marketing fluff. That’s manufacturing competence.

Ready to source pearls drilled correctly the first time? Contact us with your specifications.

Frequently Asked Questions

Can half-drilled pearls be converted to full-drill?

Yes, but it needs specific tools and could hurt the pearl. The hole that is already there is a good place to start, but it’s hard to line up the second side. Most manufacturers won’t try this conversion because it has a significant danger of breaking.

Are full-drill pearls more likely to crack than half-drill?

Only during the drilling process itself. Once properly drilled, full-drill pearls aren’t inherently weaker. The nacre around the hole doesn’t spontaneously fail. However, improper drilling technique—especially single-pass drilling—does cause stress fractures.

What glue should I use for half-drill pearl settings?

Two-part epoxy specifically rated for jewelry. Devcon 5-minute is the industry standard. Apply a small amount inside the hole, insert the post, remove excess immediately with alcohol-dampened tissue, and cure for 24 hours. Don’t use cyanoacrylate (super glue)—it doesn’t provide sufficient bond strength for jewelry applications.

Can I request custom hole diameters larger than standard?

Yes. Professional wholesale pearls suppliers can drill holes from 0.8mm up to 3mm+ depending on pearl size. Larger holes require appropriate pearl dimensions—you can’t drill a 2.5mm hole in a 5mm pearl. Specify your threading material diameter and the supplier should recommend appropriate sizing.

How do I know if a supplier’s drilling quality is acceptable?

Request samples before placing large orders. Check hole alignment (full-drill), consistent depth (half-drill), minimum chipping at entrance points, and centring. Wires should pass through full-drill samples without binding. Test-fit your findings for half-drill compatibility.

Do baroque or potato-shaped pearls drill differently than round pearls?

Yes. Irregular shapes require custom positioning to ensure the hole placement makes sense for the final jewelry application. Top-drilling baroque pearls creates drop pendants; side-drilling creates different design options. Work with a pearl manufacturer who understands design intent, not just technical drilling specs.

Is ultrasonic drilling better than traditional drilling for pearls?

Ultrasonic drilling lowers the risk of heat buildup and cracking for harder materials or holes with very small diameters. But for regular pearl drilling (0.8mm-2.5mm holes in freshwater pearls), current rotary drilling with the right coolant and technique works great. The operator’s skill is more important than the way they drill.